Carbon Coat is an exceptional coating for rust prevention – but its effectiveness depends on proper application and maintenance. Carbon Coat is not a one-time, bulletproof solution. However, scheduled yearly maintenance will ensure lasting protection, even in high-use or high-humidity environments.

Preparation: Laying the Foundation for Durability

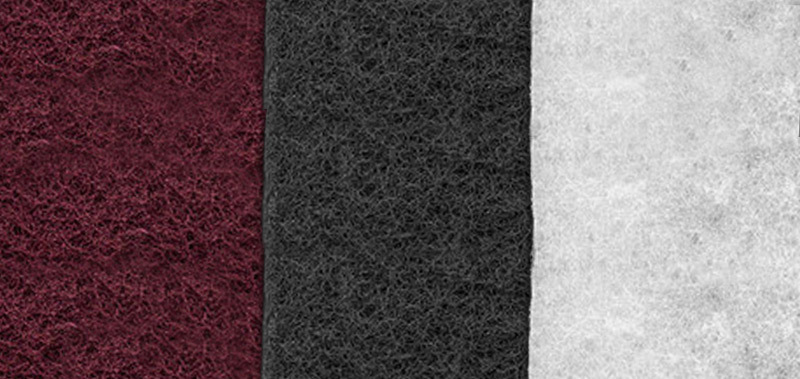

Use the Carbon Coat Prep Kit

Even on new tools, it is highly recommended to use the Carbon Coating Prep Kit to smooth out the surface.

Progress through the grits of our Abrasive Pads, using Reconditioning Oil, as instructed in the kit.

This will create a semi-polished surface that enhances adhesion and longevity, and will yield a higher cross-link density in your Carbon Coat.

Application: Building a Protective Barrier

Layering Recommendations

It takes approximately 2 layers to form a seal on a smooth surface. Each additional layer acts as a wear layer, providing added protection against corrosion and tool wear.

For ordinary use in normal environments, we used to recommend 3-4 layers, but as we’ve seen how Carbon Coating performs in more shops and more conditions, we now recommend a minimum of 4 layers, even for ordinary use and conditions.

In a high-use or high-humidity environment, it is best practice to start with a thicker initial application of Carbon Coat. 6 layers of Carbon Coat is the minimum recommendation. Starting with 6 layers will result in a thicker film build, providing more material to wear against and an increased barrier to fight humidity.

Maintenance: Prolonging Protection

Reapplication Schedule

For Carbon Coat to be effective in the long term, we have to replace the layers that are worn off due to use. The key is to reapply on a schedule before we see any corrosion.

In shops with normal usage, yearly maintenance is recommended. In a high-use environment, wear on the coating will happen faster, so reapplication will need to be more frequent. If you run a lot of board-feet across your tools, or if you are protecting tools in a professional shop, add an additional 4 layers of Carbon Coat every 6 months.

Using Carbon Glide

Regular applications of Carbon Glide add an extra protective layer, reducing wear on the Carbon Coat itself. Applying Carbon Glide is quick and easy. When you feel an increase in friction, simply spray more Carbon Glide.

In a high-use environment, spraying Carbon Glide weekly or even daily will yield excellent results.