Introduction

Carbon Method ceramic nanofinish is like adding a nanoscale layer of glass to your piece of furniture. This super-hard layer provides superior protection against water, oil, and chemicals - including the dreaded water ring. These nanofinishes also provide an unparalleled brilliance to the look of your piece, due to how light interacts with this protective ceramic layer.

More than just a finish, ceramic nanofinish goes on top of your regular finish, enhancing its protection and appearance. Ceramic nanofinishes are applied by hand, buffed, and allowed to cure.

For maximum protection, the Carbon Method Ceramic Nanofinish uses 2 to 3 layers of "Hard Coat" 9h+ ceramic for wood, followed by at least 2 layers of "Top Coat" 9h ceramic for wood.

Hard Coat provides an ultra-thin, ultra-hard layer of protection between the wood finish and the wear layer. Top Coat acts as a thicker wear layer that provides heat, water, oil, and chemical resistance as well as a stunning appearance.

Welcome to the future of nanofinishing.

Overview

Please read directions thoroughly before beginning application. If you have any questions, video instructions and contact information are available at carbonmethod.com.

Before any surface preparation or application, put on latex or nitrile gloves. Wear gloves during the entire preparation and application process. This prevents transfer of skin oils to the working surface.

Apply in a well-ventilated area. Ensure that the area is controlled to prevent dust or other contaminants.

Place cap on any bottles when not in use.

We recommend that you test the application on a piece of scrap that is finished in the same manner as your desired surface.

Please discard any used Carbon Method Coating Cloths. Once dried, the material is of course extremely hard, and has many grinding edges when dried into the coating cloth. This makes it a real risk for scratching any surfaces it's accidentally applied to, and just isn't worth the risk. Once the material has dried in the coating cloth, simply discard it and use another.

Before the first layer of application, remove all debris from surface to be treated. If using a rag, do not reuse for later steps, as dust from the cloth may become embedded in the coating.

After dust and particles have been removed, use a second clean cloth, wetted in a cleaning solution, to remove any unseen contaminates. Consult your chosen finish for information on compatible cleaning agents. Wipe the work surface with your cleaning agent, following the grain of the wood. Ensure that the wood is wiped thoroughly.

To achieve the best results from your nanofinish application, use "NanoPrep" preparation spray for nanofinish application before the first layer of Hard Coat. Remove any visible dirt and dust from your piece with a microfiber towel or compressed air, spray NanoPrep onto a lint-free cloth, and wipe the surface thoroughly to remove any oil or contaminants. Once the surface is dry, repeat, and allow to dry before proceeding.

Prior to Application, make certain the cleaning agent has been fully removed, or has evaporated completely. Applying ceramic nanofinish to a wet surface will cause uneven application and may diminish the overall protection and appearance of your final product.

Choose a working area on the surface less than 9 square feet. If your work surface is greater than 9 square feet, multiple application areas are recommended. If this is your first time applying Carbon Method ceramic nanofinish, we advise working with smaller areas, around 4 square feet. This will make application easier and help to lower the learning curve with the pace of application.

For additional application areas, overlap existing sections as little as possible while still providing coverage. This overlap can be blended into an even surface in the Leveling / Buffing step of the application process.

Ceramic nanofinishes cure quickly. Hard Coat and Top Coat have a working time of 1 to 5 minutes for each section or layer of application, depending on local humidity and temperature. You will need to allow each layer to cure for 60 minutes, depending on conditions, before applying the next layer.

Allow 24 hours between the application of Hard Coat and the application of Top Coat.

1. Preparation

Thoroughly shake bottle of Hard Coat or Top Coat ceramic nanofinish.

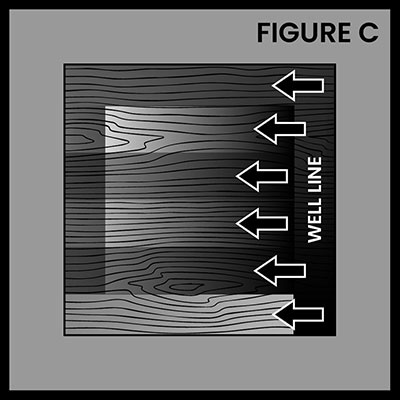

Wet the center of your Carbon Method Coating Applicator Block system with ceramic nanofinish, making certain to thoroughly saturate your Carbon Method Coating Cloth.

Add more as needed. Always thoroughly shake bottle before re-saturating the Coating Cloth.

2. Application

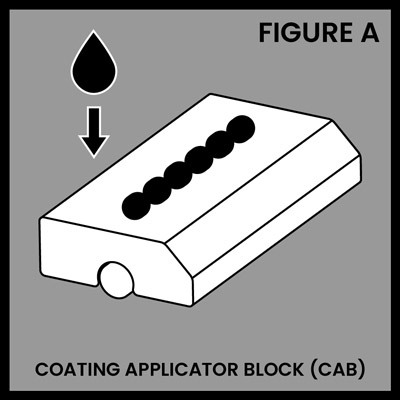

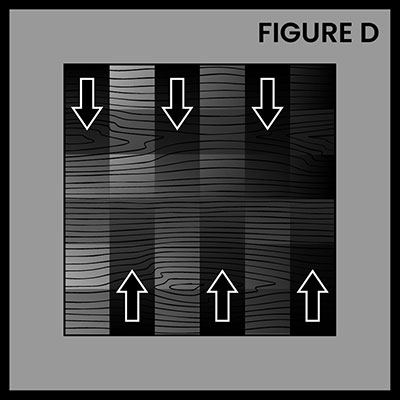

Create an initial "well line" by applying ceramic nanofinish in a straight line against the grain. Block in your working area by outlining a rectangle with the saturated Coating Applicator Block.

The initial application line or "well line" will contain more ceramic nanofinish than following strokes. It is important to draw from this "well line" during the initial layer application, in order to ensure even application.

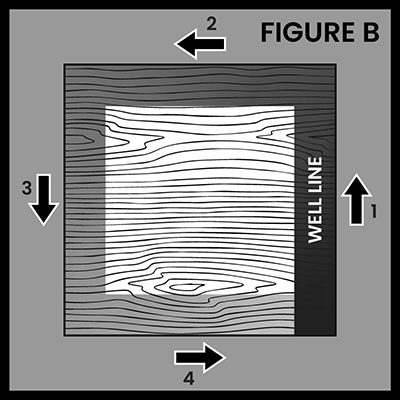

After the working area has been blocked in, draw the Coating Applicator Block from the well line to the opposite edge of the working area, until ceramic nanofinish has been applied to the entire working area, making certain that no part of the working area is dry of ceramic nanofinish.

Change directions 90 degrees, and draw the Coating Applicator Block in a pattern perpendicular to the path of the initial application, alternating directions with the application.

Continue alternating directions until the surface tension begins to provide a slight resistance. This drag is produced when the solvent begins to evaporate and the product catalyst has started activating.

It is always better to apply too much ceramic nanofinish, as excess material can be addressed during the Leveling / Buffing step. Do not over-work the surface during this stage, as this can lead to scratches and uneven application.

3. Leveling

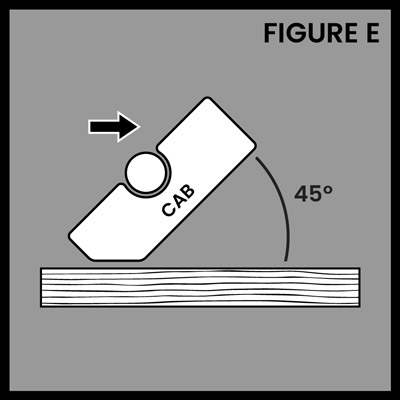

After the partial cure of 60 to 90 seconds, level the coating by removing excess material. Lightly drag the beveled edge of the Coating Applicator Block across the surface; the beveled edge will give you the perfect 45-degree angle.

Do not apply pressure at this time. Allow the weight of the Coating Applicator Block to wick the high spots from the work surface. Allow the work area to cure for an additional 60 to 90 seconds prior to buffing.

4. Buffing

Using a clean Carbon Method microfiber cloth, fold the cloth into quarters. Each buffing must be done with a clean portion of the cloth, so continue unfolding a clean quarter of the cloth for each buffing.

Lightly buff the application area, using a circular motion. The application area should begin with a stiff or tacky feel. Through buffing, the application area will gain a slight sheen and resistance will decrease until the surface is slick, as the buffing process is completed - similar to buffing out a paste wax. Do not apply excessive force during the buffing stage, as this may cause uneven areas in the final finish.

5. Additional Sections

Repeat steps 1 through 4, working in up to 9 square foot sections, until the entire surface has been coated, making sure to overlap sections slightly.

6. Blending

Inspect the full application. Any areas that appear glossier than others are called "high spots". This can happen on overlapping areas, areas that were not buffed thoroughly, or from uneven application. "Level It" blending solution for ceramic application will allow you to reflow select areas of your ceramic nanofinish application, ensuring a perfect application every time.

Thoroughly spray "Level It" on a clean buffing cloth, and buff out the high spots.

"Level It" can be applied up to 4 hours after initial application to reflow trouble areas.

7. Application of Additional Coats

Do not reuse Coating Cloths, as partially-cured ceramic nanofinish within the Coating Cloth will cause scuffing in your surface finish. For future applications, use a fresh Coating Cloth.

Allow Hard Coat to cure for 60 minutes before applying additional layers of Hard Coat by repeating steps 1 through 6. For optimal protection, 2 to 3 layers of Hard Coat are recommended.

After the base layers of Hard Coat have been allowed to cure for 24 hours, Top Coat can be applied, following steps 1 through 6, above. Before applying Top Coat, use a soft rag to remove any dust that has settled.

Allow Top Coat to cure for 60 minutes before applying additional layers of Top Coat by repeating steps 1 through 6. For optimal protection, 2 layers of Top Coat are recommended. For a glossier finish, add more layers of Top Coat.

Use and Maintenance

After your final layer of Top Coat has been applied, allow fully-coated surface to cure for a minimum of 24 hours. The coatings will continue to harden for up to 7 days. Do not introduce water or any other liquids to a coated surface for at least 24 hours.

For best results, reapply Top Coat every 12 months for home use, and every 4 to 6 months for high-use settings such as restaurants and other work areas. This reapplication will serve to protect your base coat, fill any micro-scratches, and ensure continued protection and performance.

Standard cleaning products can be used on your new finish. For best results, weekly or monthly restoration with "Ceramic Care" ceramic-infused maintenance spray for furniture is recommended.

Spray Ceramic Care on your finished surface and spread out thoroughly with soft rag. Wipe up any remaining liquid and allow to dry. Finally, lightly spray Ceramic Care on to a microfiber towel and buff to a streak-free shine. Spray multiple applications to build greater protection.

Storage

Store all products in original packaging, including tubes where applicable. Prevent from freezing.

Frequently Asked Questions

Can I apply Ceramic Nanofinish to bare wood? No, nanofinish is best applied to wood that has already been finished.

Will Ceramic Nanofinish work on my finish? Our Nanofinish works over any wood finish, including hardwax oils, oil-based finishes, water-based finishes, rewetting finishes (shellac and lacquer), varnish, spar urethane, etc.

How long should I let my finish cure before applying Ceramic Nanofinish? Whatever your finish is, it should be fully cured to the manufacturer's recommendation before applying Ceramic Nanofinish. In the case of Rubio Monocoat, for example, that would be 7 days if using the 2c hardener.

Will ceramic nanofinish work over epoxy, or epoxy flood coat? Absolutely!

What is the temperature range for application? The minimum temperature we recommend is 50 °F. At the lower temperature end of the temperature range, we recommend waiting 90 minutes between layers.

There isn’t really a maximum temperature. However, when it gets warm - 80 °F+ - working times will decrease dramatically, making application more difficult. You will need to work quickly during application. You will also need to be more diligent when buffing. Waiting more than 60 seconds before buffing could make buffing difficult, as the coating is curing very quickly, leading to an increased chance of high spots.

What do I do if I have high spots after curing? If you notice high spots after an application is cured, you can attach one of our grey abrasive pads to a random orbital sander. Go over the high spots first, then go over the whole piece to even out the scratch pattern, making sure not to go through your finish. You can then recoat, starting with Hard Coat and following the application process again. If that does not fix it, you will have to completely remove the nanofinish, re-apply your chosen wood finish, and start the finishing process again.

Is your Ceramic Nanofinish food safe? While our Nanofinish does not carry any food safe certificates, our Nanofinish works beautifully on wood countertops. However, we do not recommend Nanofinish coatings for cutting boards. The issue is that knives will cut through the coating and could possibly transfer to food. Nanofinish coatings are not safe for human consumption - but you could use them for a charcuterie board as long as there is no cutting on the board.

How do I reapply Ceramic Nanofinish? After some time, our Nanofinish may lose some of its luster. This is from wear and tear. Micro-scratches reflect light differently than the crystal clear Nanofinish coating. Reapplying our Nanofinish is easy. Simply clean the piece with NanoPrep then reapply 2-3 layers of Top Coat.

Can you use Nanofinish outdoors? Yes, our Nanofinish is great on top of an outdoor wood finish.

Is a Ceramic Nanofinish containing graphene superior for wood? This is an interesting topic. Our competitors would lead you to believe that Graphene is far superior to an SiO2-type of formulation. The truth is that there is a lot more at play than an oversimplification of "Graphene is Better". We are confident that our coatings will exceed expectations and outperform competitive products when placed side by side.

Does Ceramic Nanofinish yellow over time? Unlike polyurethane or clear epoxy, our Nanofinish does not yellow over time.

Can I get protection without gloss? Absolutely! Just use Hard Coat until you reach the desired sheen. Hard Coat is inherently less glossy than Top Coat. You won’t get the full protection of the 2-part system, but it will still provide plenty more protection than just wood finish.

Can I wash the buffing towels and applicator blocks? No, it is best to not introduce our coatings to your water supply. Throw the pads in the trash. We like to reuse the buffing towels for glue cleanup in the shop.

Additional Questions?

Contact us by calling 616-366-4232 or emailing cs@carbonmethod.com.